CNC Router

Introduction

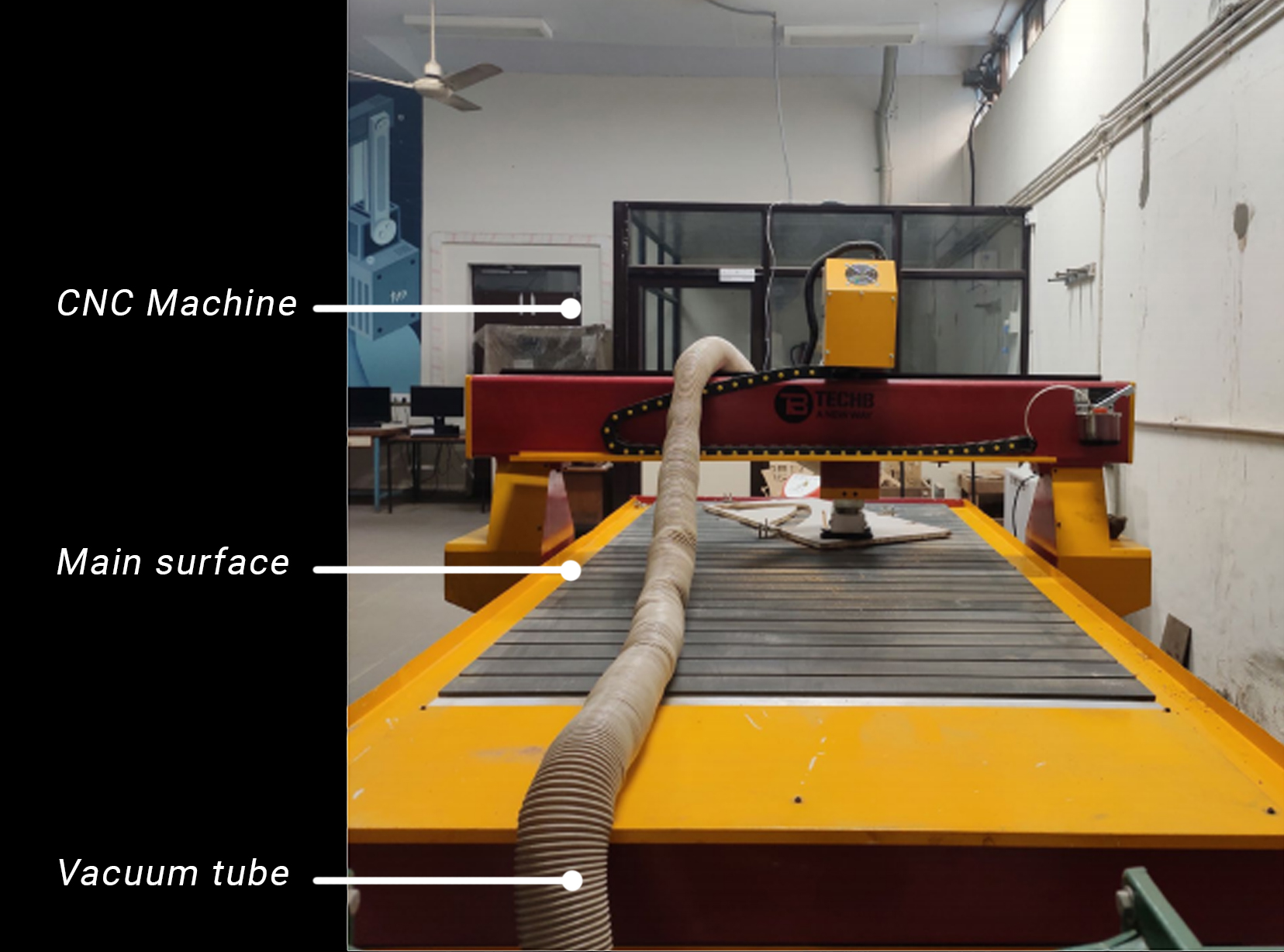

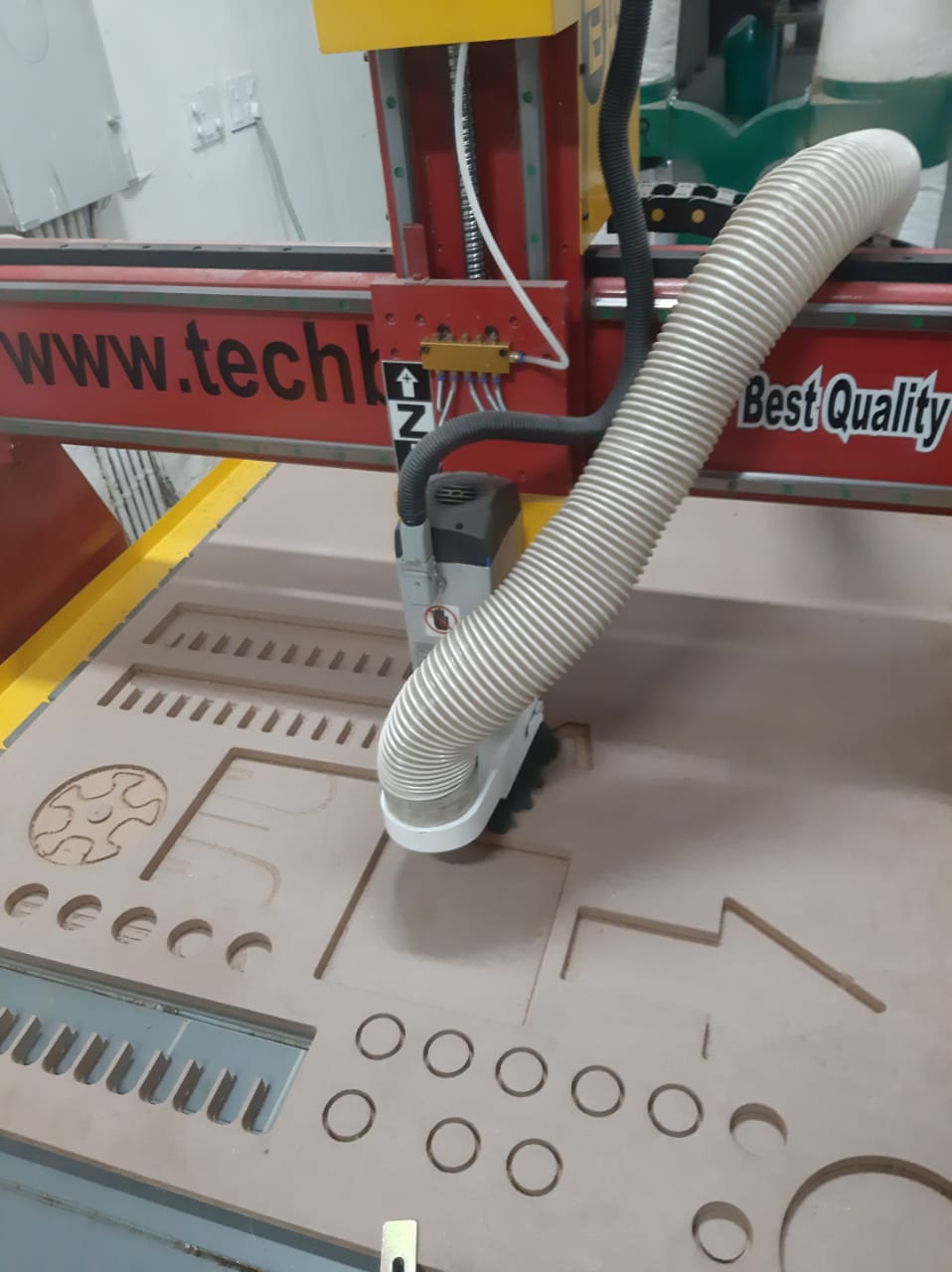

The CNC router is used to fabricate a product using subtractive manufacturing. A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminium, steel, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut mortises and tenons. The software used to operate upon the CNC router is Aspire 3D

Set-up and process

- Make the vector file in Aspire or import a 2D drawing in to the software

- Make adjustments to the properties like where to cut, depth, number of cycles,how it will cut.

- Export the file and transfer it to a usb drive

- Insert the usb to the controller in the CNC machine and give the reqd. commands.

- We connect the vacumm cleaner and turn it on.

- We set the origin point for the tool to start cutting

- one round of cut is made in the air to make sure the directions and drawing is within the required bounds.

- We press go to start the process.

Precautions to be taken

- - Ensure drill bit size is precise as different sizes will give different levels of accuracy.

- - Use gloves and eye protection.

- - Always use vacuum to keep the dust and small particles from endangering your process.

- - Keep an extra layer of material under the main material to cut so as to avoid damaging the cnc bed

- - Keep suffiient overlapping depth cut for each cycle

Output

Using a vector file from the internet we cut a chicken "MURGI".